FX219G5 – Silicone Potting & Encapsulation Compound

Everwide FX219G5 Silicone Potting Compound – high-thermal, UL94 V-0 silicone potting for electronic modules. Compare with Shin-Etsu KET-132 silicone potting.

LOCTITE® 221™ is a low-strength, anaerobic threadlocker designed for locking and sealing threaded fasteners that require disassembly with standard hand tools. It cures in the absence of air between close-fitting metal surfaces, preventing loosening and leakage due to shock or vibration. It is particularly suited for applications like set screws, small diameter, or long engagement length fasteners.

| Property | Value |

|---|---|

| Specific Gravity @ 25°C | 1.05 |

| Flash Point | See SDS |

| Viscosity (Brookfield RVT, 25°C) | 100 – 150 mPa·s (cP) |

| Property | Value |

|---|---|

| Coefficient of Thermal Expansion (ISO 11359-2) | 100 × 10⁻⁶ K⁻¹ |

| Coefficient of Thermal Conductivity (ISO 8302) | 0.1 W/(m·K) |

| Specific Heat | 0.3 kJ/kg·K |

| Property | Value |

|---|---|

| Breakaway Torque (ISO 10964, M10 Steel Nuts & Bolts) | 5 – 12 N·m (40 – 110 lb·in) |

| Prevail Torque (ISO 10964, M10 Steel Nuts & Bolts) | 2 – 8 N·m (20 – 70 lb·in) |

| Breakloose Torque (ISO 10964, Pre-torqued to 5 N·m) | 9 – 21 N·m (80 – 90 lb·in) |

| Compressive Shear Strength (ISO 10123, Steel Pins & Collars) | 3 – 10 N/mm² (430 – 1,450 psi) |

| Condition | % of Initial Strength Retained |

|---|---|

| Motor Oil (125°C) | 95 – 100% |

| Unleaded Gasoline (22°C) | 95% |

| Brake Fluid (22°C) | 90 – 95% |

| Water/Glycol 50/50 (87°C) | 80% |

| Acetone (22°C) | 90 – 100% |

| Ethanol (22°C) | 90 – 95% |

Everwide FX219G5 Silicone Potting Compound – high-thermal, UL94 V-0 silicone potting for electronic modules. Compare with Shin-Etsu KET-132 silicone potting.

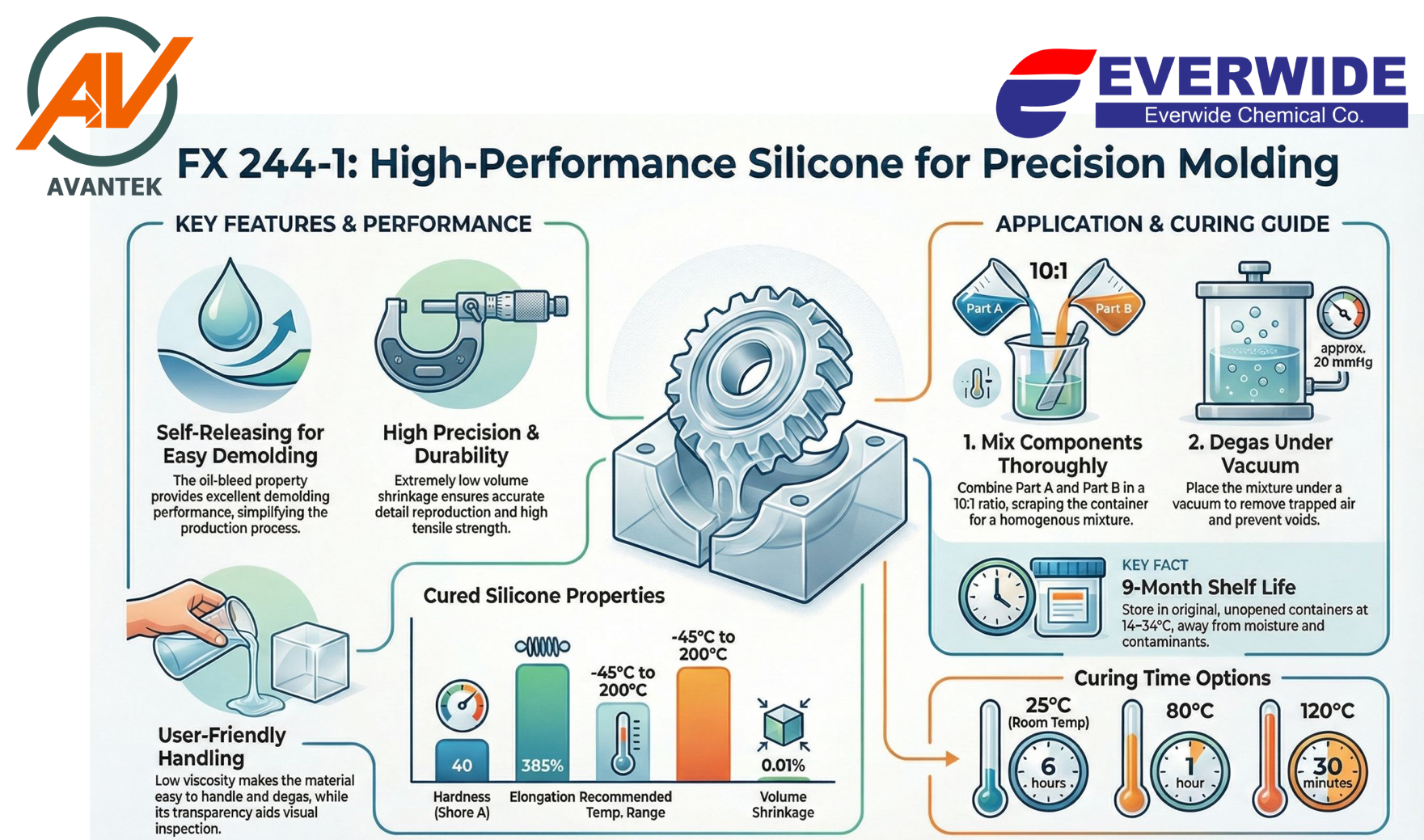

FX244-1 A specialized two-part silicone rubber designed for creating high-precision molds. This material features a unique oil-bleeding property that creates a self-releasing surface, eliminating the need for external non-stick sprays during demolding.

As the year draws to a close and the Christmas season arrives, Avantek Viet Nam would like to extend our warmest Christmas greetings to all our valued customers, partners, and friends.

Partial Gasket & Seal Strategies Using Henkel Loctite SI 5910

Gasket sealing is a core part of many industrial assembly and maintenance operations — from automotive engine housings to HVAC covers and machinery flanges. When selecting a gasketing solution, you need something that forms reliably in place, resists movement and fluids, and simplifies application — which is where Henkel Loctite SI 5910 fits perfectly

Avantek Viet Nam is a dynamic MRO, direct materials and equipment supplier that brings advanced technological solutions to maximize satisfaction of customers.

We are expert in import and export of adhesives, accessories and equipment in both domestic and cosmetic industrial fields, production and technology research and development.

Our solutions promise to bring best optimal effectiveness along with competitive prices, excellent customer services, dedicated on-site support.

Office address: The Verosa Park, 39 street 10, Quarter 2, Long truong Ward, Ho Chi Minh City, Viet Nam

Website: avantek.vn

Email 1: info@avantek.vn

Email 2: long.pham@avantek.vn

Tel: (+84) 944 415 762

Copyright © AVANTEK VN CO., LTD

Leave your information or contact via Hotline, our Customer Support Technical team will contact you immediately!