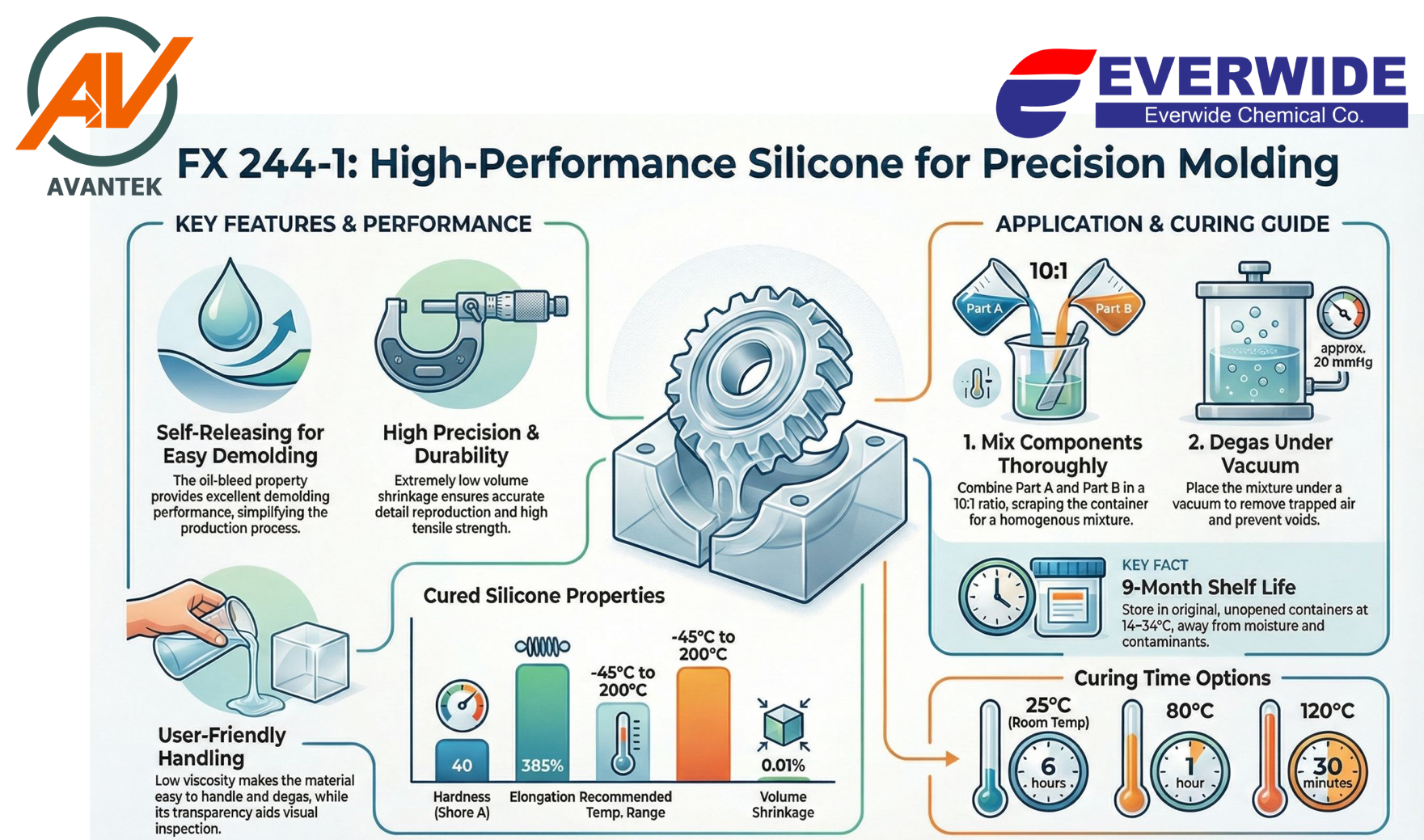

Everwide FX244-1: High Performance for Precision Molding

FX244-1 A specialized two-part silicone rubber designed for creating high-precision molds. This material features a unique oil-bleeding property that creates a self-releasing surface, eliminating the need for external non-stick sprays during demolding.