FX244-1 – Oil-Bleeding Silicone Rubber for Precision Molding

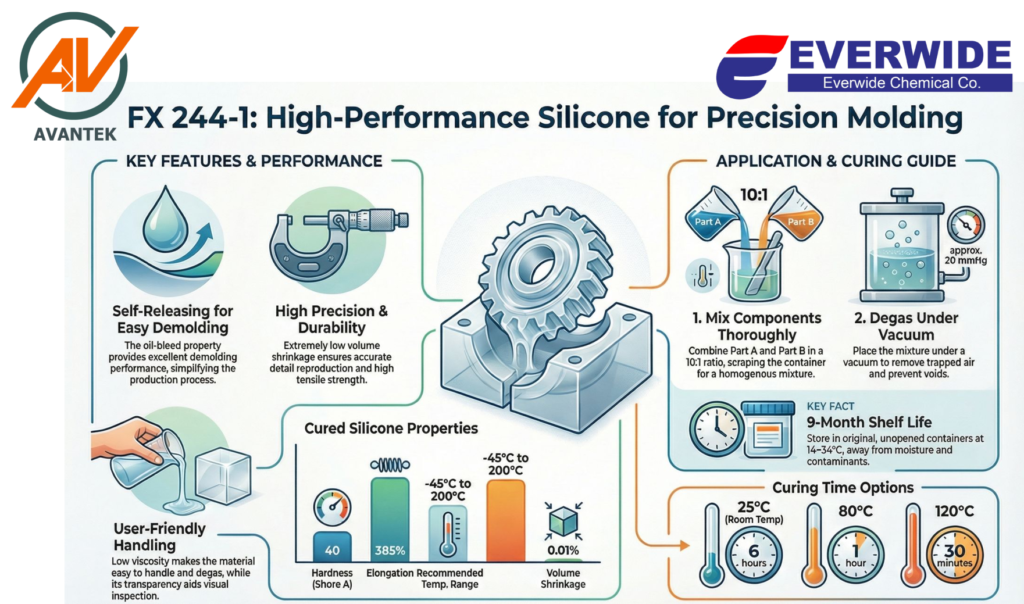

FX244-1 is a two-component, addition-cure liquid silicone rubber (LSR) engineered for high-precision molding applications. With a mixing ratio of A:B = 10:1, it cures at room temperature or under heat to form a high-strength, highly elastic silicone rubber with excellent dimensional stability and durability.

A standout characteristic of FX244-1 is its oil-bleeding self-releasing property, which enables easy demolding without external release agents. Combined with low viscosity, high transparency, and strong mechanical performance, FX244-1 is ideal for molds that require fine detail reproduction and long service life.

Key Functions

-

Self-Releasing Mold Surface

Oil-bleeding behavior improves demolding efficiency and reduces damage to molds and cast parts. -

High-Fidelity Detail Replication

Low viscosity enables excellent flow into fine features and complex geometries. -

Dimensional Stability

Ultra-low volume shrinkage (~0.01%) ensures accurate mold dimensions. -

Mechanical Durability

High elongation and tear strength support repeated use and long mold life. -

Thermal & Electrical Reliability

Maintains performance from -45°C to 200°C and offers excellent electrical insulation.

How It Works

FX244-1 functions through an addition-curing (platinum-catalyzed) crosslinking reaction:

-

Mixing (A:B = 10:1)

The silicone base (Part A) and curing agent (Part B) are accurately weighed and mixed until homogeneous. -

Degassing

Due to its low viscosity, trapped air bubbles can be easily removed under vacuum, ensuring void-free molds. -

Curing & Crosslinking

At room temperature or under heat, the silicone undergoes a controlled crosslinking reaction, forming a flexible yet high-strength elastomer. -

Self-Release Mechanism

During and after curing, a controlled oil-bleed effect develops on the surface of the cured silicone, providing natural release properties that reduce adhesion to cast materials and mold masters. -

Long-Term Performance

Once cured, the silicone maintains elasticity, dimensional accuracy, and mechanical strength over repeated casting cycles and wide temperature ranges.

Typical Applications

FX244-1 is well-suited for applications requiring precision, durability, and easy demolding, including:

-

Precision Mold Making

-

Silicone molds for casting resin, PU, epoxy, wax, and plaster

-

Molds requiring fine surface detail and high transparency

-

-

Industrial Tooling & Prototyping

-

Master molds for short-run or pilot production

-

Prototyping of industrial and technical components

-

-

Art, Craft & Decorative Casting

-

Transparent and decorative molds with high aesthetic quality

-

-

Electrical & Technical Components

-

Flexible insulating molds and parts requiring high dielectric strength

-

Benefits Over Traditional Products

Compared with conventional rubber, silicone, or non-oil-bleeding mold materials, FX244-1 offers clear advantages:

-

No External Release Agent Required

Reduces processing steps, cost, and surface contamination. -

Superior Detail Accuracy

Outperforms traditional high-viscosity rubbers in reproducing fine details. -

Lower Shrinkage

Ensures better dimensional accuracy than many standard silicone or rubber systems. -

Longer Mold Life

High elasticity and tear strength reduce cracking and wear over repeated use. -

Wider Temperature Resistance

Performs reliably in applications where conventional rubbers may harden or degrade. -

Cleaner, More Efficient Processing

Addition-cure system avoids by-products and supports consistent, repeatable results.

Storage & Shelf Life

FX244-1 should be stored in a cool, dark environment between 14–34°C. When kept in original, unopened containers, it has a shelf life of 9 months. Contact with sulfur, amines, phosphorus compounds, and certain metal ions should be avoided to prevent curing inhibition.

FX244-1 is an ideal solution for precision mold making, offering reliable processing, excellent mechanical properties, and consistent performance for industrial and technical applications.